E-commerce

PRECISION INDUSTRY

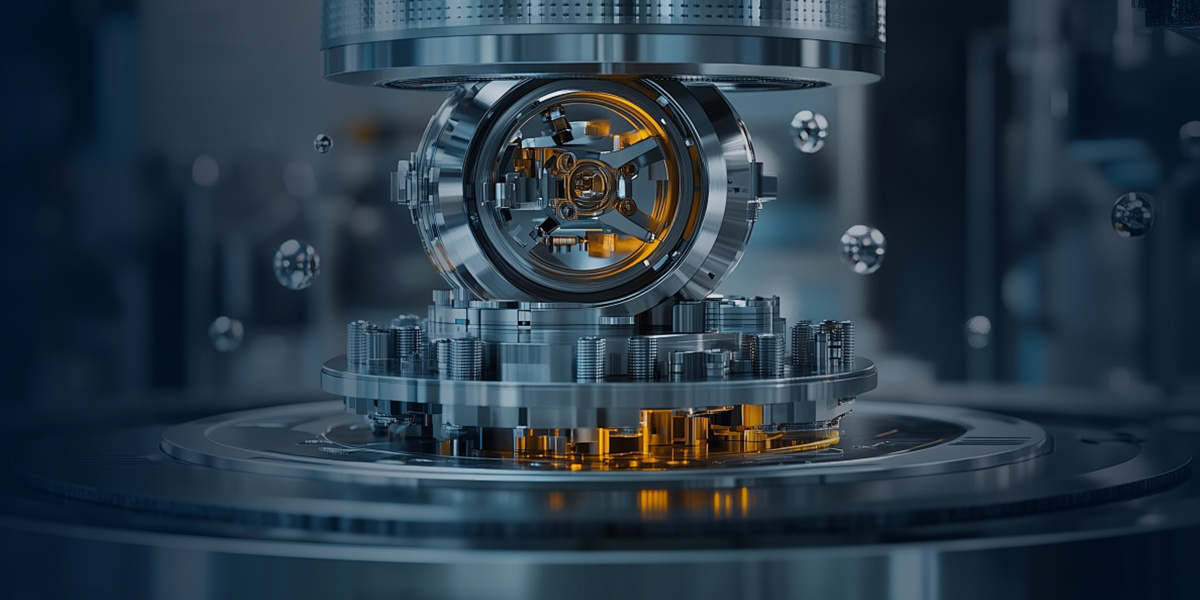

Precision Industry

Welding plays a crucial role in the precision industrial sector. Here are several important functions of welding in this industry:

1. Improve product quality:Precision spot welders and precision laser welding machines can provide high precision and high-quality welding, which is essential for ensuring the stability and reliability of products.

2. Enhance production efficiency:Precision welding technology can quickly complete welding tasks, reducing the time and error rate of manual operations, thereby improving the overall production efficiency of the production line.

3. Adapt to complex structures:Precision welding technology can meet the welding needs of complex geometric shapes and small sizes, which is difficult to achieve with traditional welding methods.

4. Promote the application of new materials:Precision welding technology can handle various materials, including metals and plastics, which promotes the application of new materials in precision industries.

In summary, welding technology in the precision industrial sector is not only a fundamental means of connecting materials but also a key factor in improving product quality, production efficiency, and innovation capability. With continuous technological advancements, the role of welding in precision industries will become even more significant.

The welding protection products produced by our company are widely used in the electronics industry, automobile industry, communication industry, digital innovation, precision industry and other industries, with a broad market and good prospects.

In the electronics industry, solder protection tools are mainly used in electronic assembly scenarios, such as soldering components or components on printed circuit boards. In the automotive industry and communications industry, welding protection tools are mainly used in the manufacture of automobiles and their parts, and the manufacture and maintenance of communications equipment. In the digital innovation and precision industry, welding protection tools are used to optimize production processes.

As a traditional basic process and technology of manufacturing industry, welding has a short history of application in industry and has developed rapidly. Harmful factors such as harmful gas, harmful dust and smoke, arc radiation, high frequency electromagnetic field, noise and radiation will be produced in the welding process. If the protection is improper, it may lead to chronic poisoning of workers or occupational diseases such as blood diseases, pneumoconiosis, electro-optic ophthalmia and skin diseases. Therefore, the use of welding protection tools can effectively protect the health of workers, improve efficiency and improve product quality.

Headquarters: Guanggu Electronic Industrial Park, No.28, Gaoxin 4th Road, Donghu High-tech Zone, Wuhan, Hubei Province

Base: Haiying Road, High-tech Industrial Development Zone, Qidong City, Nantong City, Jiangsu Province

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

SAF Coolest v1.3.1.2 设置面板 WSJSX-AOFV-QSASE-XAV

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page